Delivering a quality plumbing system to our clients requires collaboration and coordination from design development to the certificate of occupancy. At WLHS we continually strive to implement our expertise into the most efficient design possible. Each project is unique, and our experience provides the institutional knowledge required to bring the concept to reality.

New Construction Plumbing Systems

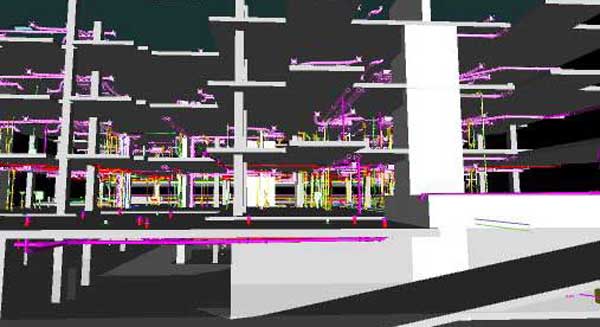

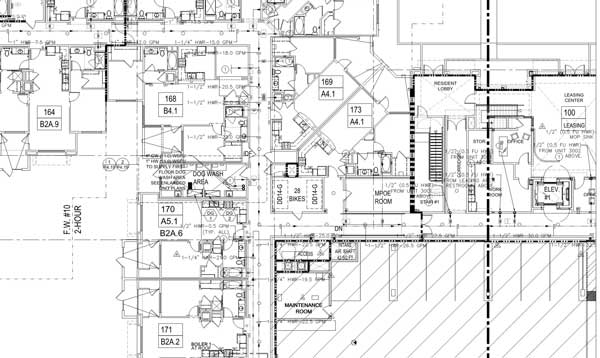

W.L. Hickey Sons, Inc specializes in large plumbing systems on ground up new construction, including; Multifamily, Mixed Use, Commercial, Hospitality, Process Piping and Specialty Piping. If it’s in Div 22 00 00, we have done it! Our industry leading 3D-BIM modeling Detailing department and Building-Trade Project Management enable us to collaborate with our trade partners for an efficient MEPF system layout. Our clients trust us to push the schedule while maintaining a high quality control standard for our work. We are union affiliated and experts in prevailing wage compliance.

Engineering Services for Design-Build Plumbing Systems

Looking for an intelligent design of your plumbing system that is value engineered to current code? We offer engineering services that are industry leading in efficiency of design and installation. We can help your project from conceptual design through final certificate of occupancy. Our team knows what works for div 22 00 00 / plumbing system. We have decades of experience with the local jurisdictional authorities. This experience helps navigate potential conflicts in applicable codes as well as helps clients in selecting optional additions to their plumbing systems that provide smart solutions for future maintenance and modification to the system.

Service and Tenant Improvement on Existing Plumbing Systems

For select clients, we offer Tenant Improvement (T.I.) modifications to existing systems. We can take these projects on as design build or negotiated plan spec. Whether the project calls for the addition of a new break room with commercial kitchen hook-up or a complete floor renovation adding core bathrooms, water heaters, etc. we can help. Our team is available to work on off peak hours, as needed.

Not all plumbing systems are created equal.

Not all plumbing contractors bring the same professionalism to the project. At WL Hickey Sons, we value our relationships with general contractors, developers, fellow subcontractors, our suppliers, manufacturers and vendors. We look to make long term, mutually beneficial business relationships with every organization we do business with. From the design of the plumbing systems’ rough plumbing to the selection of material and finish fixtures, we strive to be part of the team to make the end project the best it can be!

Construction Scheduling

Time is money and the construction schedule is a prime example of this. Our typical projects range from 12 to 24 months. WL Hickey Sons knows what it takes to maintain the schedule. Our goal is to maximize collaboration by looking ahead to avoid potential pitfalls to the MEPF and structural subcontractor team. Our safety record and efficiency in the under slab / underground is excellent. We can help get the project moving forward smoothly from day one. As the structure progresses, our team is constantly looking ahead. Was there a weather event in the Atlantic? Will that effect lead times on the schedule bathtubs? Is the developer looking to change floor plans on the penthouse? Let’s discuss our rough penetrations and clearances. As a plumbing contractor, we are typically one of the first trades to mobilize and one of the last to be onsite. Having a seasoned, professional, knowledgeable trade partner for this scope has proven critical for the success of large scale projects. It’s our pleasure to be considered an industry leader in Plumbing subcontracting in the greater San Francisco Bay Area.

Fabrication

Site logistics can be tough when building in our Bay Area’s infill parcels. To minimize our foot print needed for material storage/staging at the project, we focus on pre-fabricating (pre-fab) as much of the plumbing system as possible. We have been doing this for a long while now and our system is well established. Our team coordinates internally to release the Bill of Material (BOM) for offsite fabrication. From there, our Warehouse coordinates the deliveries to take advantage of Just-In-Time (JIT) supply. Another benefit of this is we can control our recycling and reduce our carbon foot print. If your project is seeking LEED certification, we can provide very specific recaps to verify the target or goal was achieved.